Whirlpool EMEA & Odin Project

28 February,2022 - BY admin

28 February,2022 - BY admin

Whirlpool EMEA & Odin Project

Whirlpool EMEA has a historical experience into Research and Innovation European funded projects as the Horizon program and EIT Manufacturing, as an important part of its digital transformation roadmap, taking advantage from the knowledge intake driven by these activities and offering the industrial experience that is required to develop the project solution to higher levels of technological readiness.

The H2020 ODIN project represents a typical example of this virtuous exchange, allowing the industrial end users acquiring knowledge about the digitalization, virtual simulation and virtual commissioning of a workstations installed in the production lines and, on the other side, ensuring research organization the possibility to capture the real industrial business needs and face the reality of the industrial environment with its constraints and opportunities.

This type of experience has been demonstrated as very significant for an safe and robust approach to the introduction of these new technologies in the manufacturing shop floor: from Whirlpool side, the knowledge and expertise driven by the teamwork with researchers and technology experts, will be later used to further develop the digital models with a higher level of awareness on the technology potential and related risks, improving the collaboration with future technology providers and optimizing time and cost.

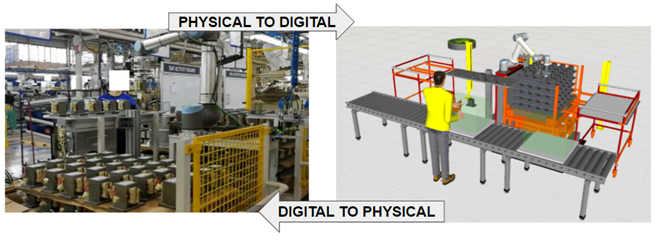

Also the path, used within the project to design and develop the solution, represents an important knowledge step for an industrial partner: the starting point of the project is the creation, at the beginning, of the “digital twin” of a physical robotized workstation, already existing in production. In the specific Whirlpool use case, this workstation is providing one component (transformer) in a physical space, called golden zone, where cobot and worker coexist without any physical barrier, to let the operator pick and install it inside the microwave oven, which is moving on a continuous flow assembly line.

This digital twin, created as a real replication of the behavior of the physical process, will then be the foundation to analyze in detail the tasks content and sequence, the spaces and trajectories used, the position of the material and of the human body to improve from different perspective like efficiency, ergonomics, safety… This digital twin will also be the starting point for potential exploitation of this approach to other manipulation processes in the production environment, giving the possibility to create, for them too, the corresponding virtual models and sustain the collaborative robotics introduction and boost the production process optimization.

Finally, also the virtual commissioning concept, tested and validated during project demonstrator, will represent a great step improvement for manufacturing process execution as, with this approach, the new digital model can be created, tested and released before being physically realized, reducing the implementation timing and installation costs and assimilability, ergonomics and safety risks.

For Whirlpool the value of this experience is great, and it will be the foundation of the next steps of collaborative robotics technology integration into its digital transformation journey, with the clear objective to use the new technological solutions, developed, implemented and validated in the ODIN project.

Get the latest news on ODIN right to your inbox!

Newsletter Permission: The ODIN project will use the information you provide in this form to be in touch with you and to provide updates and news. Please let us know if you would like to hear from us:

ODIN newsletter: You can change your mind at any time by contacting us at info@odinh2020.eu. We will not distribute your email address to any party at any time.

Comments (0)